EBC Brakes

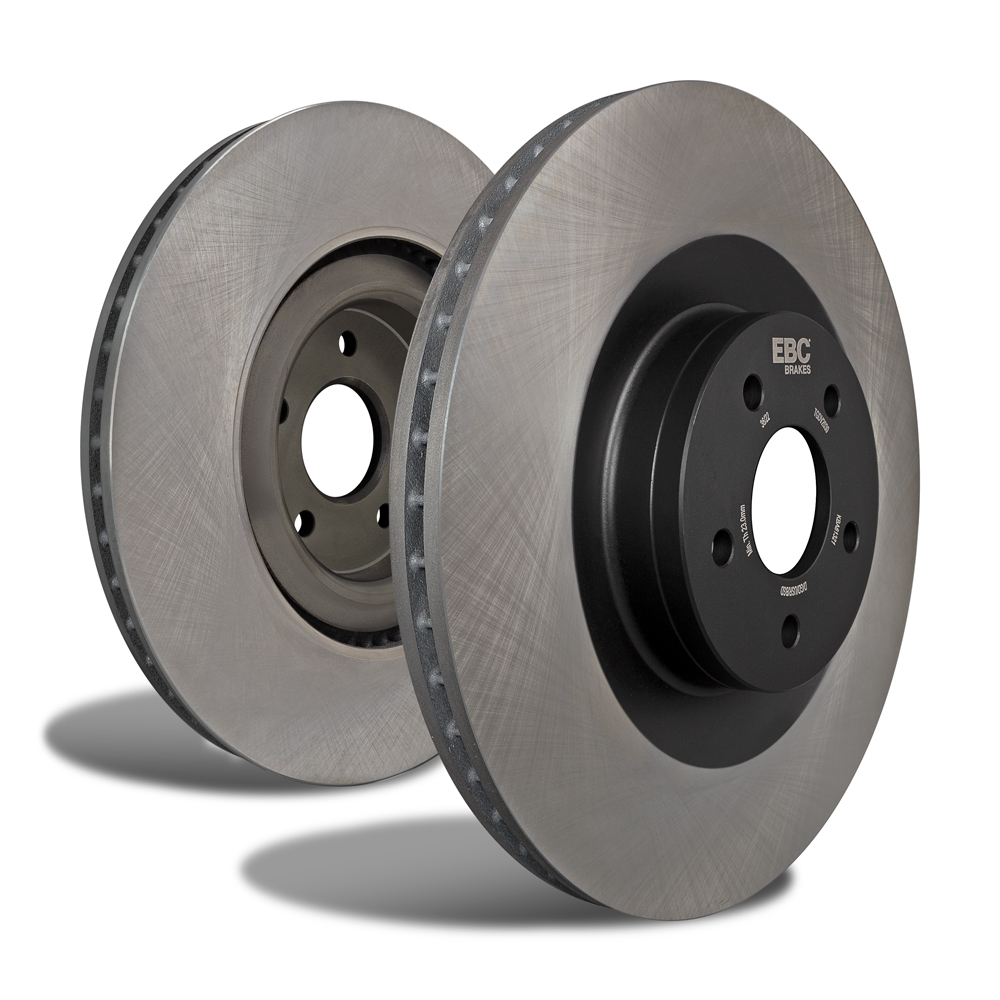

EBC D Series Rotors

Axle

Vehicle

Please Note:

We currently do not have the ability to display stock availability on our website. We are working on a solution, however in the meantime if you need to be sure of stock before purchasing your product, please be sure to contact us to confirm availability!

EBC D Series Rotor to suit Hyundai & Kia.

Sold in pairs

| i20 N 2021+ | D1878 | D2086 |

| i30 (Manual) 2017+ | D2088 | D2089 |

| i30 (Electric Brake) 2017+ | D2088 | D1902 |

| i30 N (PFL) 2017-2021 | D2201 | D2236 |

| i30 N (FL) & Sedan N 2021+ | D2274 | D2236 |

| Kona Electric | D2088 | D2121 |

| Kona Turbo AWD 2017-2023 | D2088 | D2155 |

| Kona N 2021-2023 | D2274 | D2236 |

| Veloster Turbo 2012-2016 | D1580 | |

| Cerato GT (BD) 2021+ | D2088 | D1902 |

| Picanto GT | D2234 | D1447 |

| ProCee'd (JD) 2013-2018 | D1580 | D1950 |

| ProCee'd (JD) (Electric Brake?) 2013-2018 | D1580 | D1951 |

| Stinger 2017+ | D7793 | D7796 |

| Stinger 2017+ | D2185 | D2191 |

| Stinger 3.3TT 2017+ | D7795 | D7794 |

The EBC 'D' series non-grooved brake rotors offer a superior-quality, direct replacement option, providing performance that is equivalent to or exceeds the original equipment (OE) brake rotors installed on your vehicle from the factory.

These plain rotors are the ideal choice for drivers seeking to maintain the original look (OE aesthetic) of their braking system and who prioritize quiet braking over the aggressive initial bite and increased fade resistance found in performance-grooved discs.

Exceptional Value Without Compromising Quality

Choosing the 'D' series often delivers significant cost savings compared to purchasing original equipment manufacturer (OEM) parts, sometimes costing as little as half the price, all while matching or beating the OE's quality and performance metrics.

High-Carbon Metallurgy and Durability

EBC maintains a firm commitment to high-quality materials across its entire product line:

-

Premium G3000 Alloy: Unlike manufacturers who offer lower-performance, low-carbon variants, EBC manufactures all its one-piece rotors, including the 'D' series, from the same high-carbon G3000 alloy.

-

Thermal Resistance: This superior metallurgy ensures excellent thermal capacity and high resistance against both warping and cracking, providing excellent rotor life and reliable performance.

-

The only difference between the 'D' plain rotors and EBC’s performance rotors is the absence of grooves and dimples—the foundational metallurgy remains identically high-quality.

Manufacturing Precision and Quality Assurance

Every EBC rotor undergoes stringent manufacturing processes to guarantee optimal performance and compliance.

-

Anti-Judder Machining: Rotors are machined using a meticulous twin-turning process to guarantee near-perfect parallelism. This advanced technique drastically reduces the chance of Rotor Thickness Variation (RTV), which is the root cause of frustrating brake judder (vibration).

-

Global Certification: EBC is one of the exclusive aftermarket rotor manufacturers globally to hold both TÜV and R90 approvals. This rigorous certification is a clear marker of quality, confirming full compliance with international standards, including ADRs, making the rotors completely legal for public road use in Australia.

Advanced Corrosion Protection

For maximum longevity and appearance, all finished rotors receive a comprehensive double-layer protective treatment:

-

A base Geomet® coating is applied to shield all surfaces from corrosion.

-

An additional advanced black anti-corrosion spray is applied to the visible, non-contact areas, providing extended protection against unsightly rust long after the rotors are installed.

No claims are made with regard to the legality of using any parts supplied by Cherry Tuning Pty. Ltd.

Parts are supplied for off-road use only and it is the responsibility of the customer to confirm with their local government regarding the legality of installing any parts for road use.